If you’re planning to insulate an enclosed wall or an attic in an existing building, the most common type of insulation you’ll use is loose-fill cellulose insulation, which is often installed through a process called blow-in insulation.

While blown-in fiberglass and fiberglass batts are also commonly used for attic insulation, when it comes to enclosed walls, blow-in cellulose insulation remains the most practical and cost-effective option.

Defining blow-in cellulose insulation

Blown-in cellulose insulation is a wood or paper-based material that is used to reduce the transfer of heat or cold in a building’s structural elements. This insulation is typically installed by blowing it mechanically into empty spaces within the house.

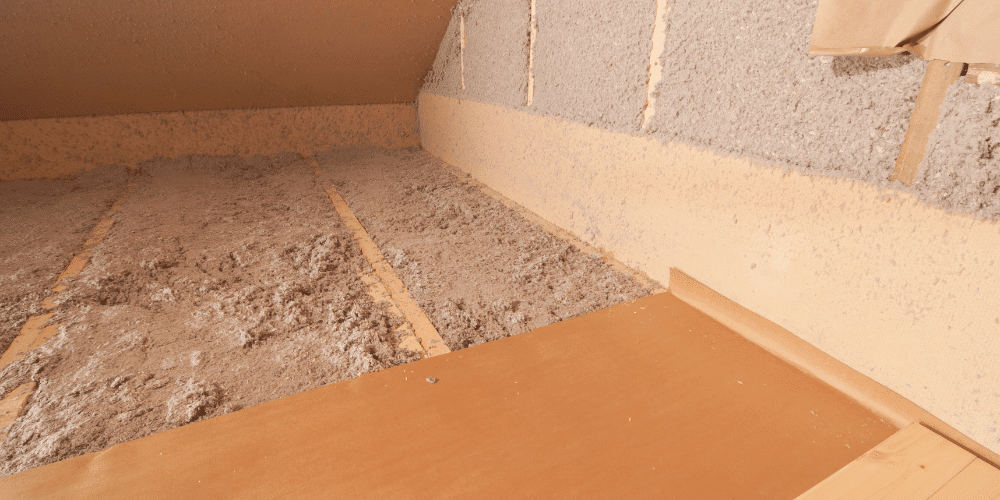

Cellulose insulation has a thick, dense, and clumpy texture that closely resembles down feathers. This texture makes it highly suitable for installation in enclosed areas such as walls and for conforming around obstructions like wires and ducts, which are commonly found in both attics and walls.

While cellulose insulation can technically be produced from any cellular plant source, such as corn cobs or sisal, commercial versions are typically made from wood, and more specifically from recycled paper products like newspapers, cardboard, and office paper. This makes cellulose insulation an eco-friendly option for home insulation.

How cellulose insulation is applied

The most commonly encountered type of cellulose insulation by homeowners is loose-fill cellulose insulation. This differs slightly from another type of cellulose insulation that is designed to be blown onto open walls, similar to spray foam. In this second type, moisture is added to the spray to help the cellulose adhere to the wall. However, with loose-fill insulation, the cellulose is dry.

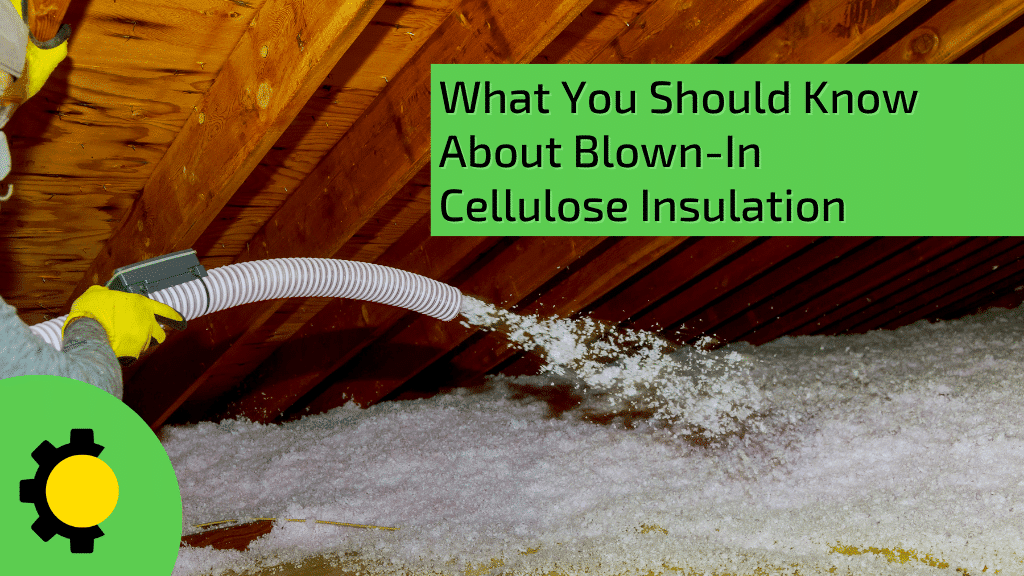

To insulate finished walls, holes are drilled in the plaster or drywall to allow access for the blower nozzle. In attics, cellulose insulation is blown parallel to the joists. It can be used on its own to fill in joist cavities without insulation or laid as a thick layer over existing fiberglass batts.

To install cellulose insulation, the following steps are typically followed:

- Densely packed bales of cellulose are loaded into the hopper of an insulation blower, which is powered by an electric motor. The bales are fluffed up by rotating teeth or prongs located at the bottom of the hopper.

- The cellulose is blown into the walls or attic through long, flexible tubes that run from the blower to an application nozzle.

- The cellulose is allowed to fill the cavities or blanket existing insulation without being subjected to any pressure. Over time, it will naturally settle.

- Any holes drilled into walls for installation are patched up and painted over to complete the insulation process.

The advantages of cellulose insulation

Cellulose insulation offers several advantages compared to other types of insulation, including:

- Loose-fill cellulose can easily conform to and fill the spaces around obstructions in walls and attics.

- Despite being relatively inexpensive, loose-fill cellulose has an R-value of approximately 3.5 per inch of thickness, which is higher than the R-value of fiberglass insulation (which ranges from 2.2 to 2.7 per inch).

- For finished walls, injecting loose-fill cellulose insulation is one of the few options available for adding insulation without having to remove drywall. The alternative would be to use fiberglass batts.

- Cellulose insulation is treated with borates, which makes it resistant to insects and vermin.

The drawbacks of cellulose insulation

Cellulose insulation has a few drawbacks to consider:

- Although settling is an advantage of blown-in cellulose insulation, it can also create problems, particularly with walls. The insulation can compress and create pockets above the settled areas, leading to thermal bridges that transfer heat or cold into the house. Settling in attics is less problematic for two reasons. First, attic spaces can be overfilled to compensate for settling. Second, when cellulose insulation in attics settles, it doesn’t create any empty spaces.

- When cellulose insulation absorbs moisture in enclosed areas, it can take a long time to dry out. This moisture can significantly decrease its R-value and potentially lead to mildew and mildew formation. Rigid or spray foam insulation is more resistant to moisture than cellulose insulation.

Is cellulose insulation eco-friendly?

Cellulose insulation can be seen as environmentally friendly because up to 85% of its materials are recycled. By comparison, fiberglass insulation claims to use between 53% and 73% recycled materials.

Cellulose vs other types of insulation

In cases where walls are closed, blowing in insulation is often the only option available. If your home is not undergoing any renovations that involve opening up the walls, holes must be drilled into them and insulation injected. The preferred method in such cases is blow-in cellulose insulation, although spray-in foam insulation is gaining popularity.

In contrast, with open walls, fiberglass roll insulation can be installed. Spray-applied foam insulation is also a possibility.

For attics, the joists are often open and accessible, making it possible to insulate them using either blow-in cellulose or fiberglass batts. However, due to obstructions like wires, cellulose insulation is often blown into attics, as it is much easier to work with.

Is cellulose insulation fire resistant?

Cellulose insulation is derived from paper, which is inherently combustible in its raw state. However, during the manufacturing process, cellulose insulation is treated with borates, which are Class I fire retardants. This means that they are effective in preventing ignition from ordinary combustibles like wood and paper, as opposed to flammable liquids or greases, which are considered Class II combustibles.

To demonstrate the fire-retardant capabilities of cellulose insulation, it is possible to conduct an experiment where a penny is placed on a bed of cellulose insulation and a blowtorch is used to apply heat. Despite the penny melting, the cellulose insulation remains unaffected, and the insulation’s insulating capacity is so effective that no heat is felt by the hand holding the experiment.

Conclusion

Blown-in cellulose insulation is a cost-effective and energy-efficient option for homeowners looking to improve the insulation of their walls and attics. While it offers numerous advantages, such as settling around obstructions and excellent fire retardation, it is important to note that it has some drawbacks, such as potential settling in walls and moisture absorption.

It is essential to use qualified and certified professionals to apply blown-in cellulose insulation to ensure that the job is done correctly and safely. They have the knowledge and experience to determine the right amount of insulation needed for each space, ensuring that homeowners get the most out of their investment.

The professionals at Sunlight Contractors are trained to handle the equipment safely, preventing any mishaps or accidents.

Contact us to have peace of mind knowing that the job is done correctly, safely, and efficiently.